YG200 High-Speed Eysdrop Aseptic Filling Production Line

The eysdrop aseptic filling line consist of four main units including unscrambler, conveyor, pure air washer, monobloc of filling plugging and capping unit. Themachine is mainly used to accomplish bottle unscrambling, conveying, air washing, dosage discharging, plug & capplacing, The entire production process is protected under laminar flow H14 and aseptic isolation cover, which isolated all working area and keep eyedrops product be filled under aseptic environment. The regional isolation protection to ensure that the eye drops sterile production. The whole machine meet the requirements of new GMP. The production line is also suitable for the production of other similar plastic bottle.

System components

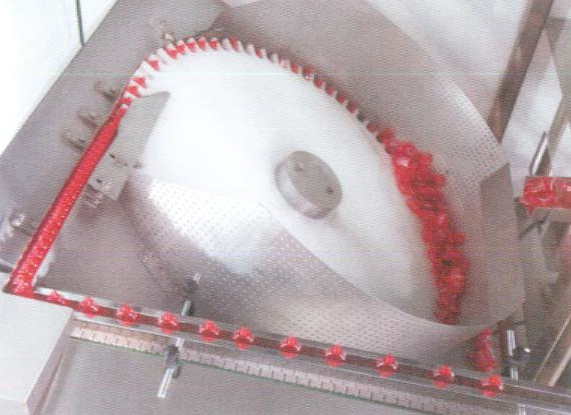

u Big bottle storage hopper, automatic unscrambling system

u Bottle conveyor, auto reject bottle fell down system

u Static elimination, bottle air washing system

u Static elimination, plug/cap air washing system

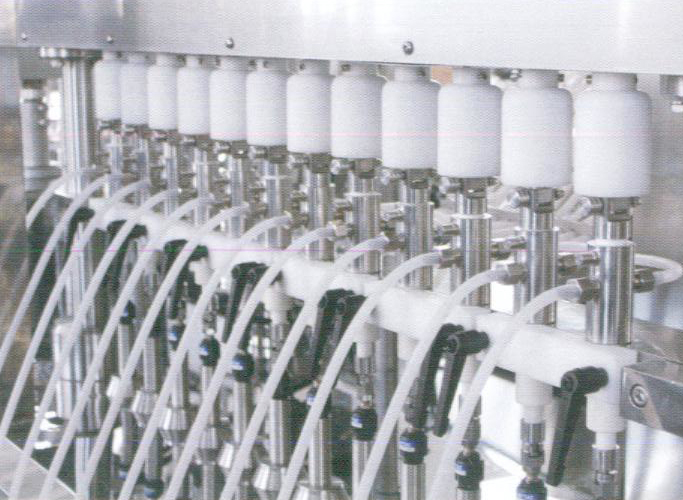

u High Precision ceramic piston pump filling system

u Vacuum suck and auto pick and place plug system

u Auto pick and place cap system

u Constant magnetic torqui, rotary screw capping system

u Laminar flow H14 and isolate hood system

|

Model |

YG200 |

|

|

|

|

Bottle used |

5-15ml plastic bottle |

|

Production capacity |

160-200bpm |

|

Filling nozzles |

12 |

|

Bottle air washing heads |

12 |

|

Plug placing heads |

18 |

|

Capping heads |

18 |

|

Filling precision |

≤±1% |

|

Qualified bottle air washing |

100% |

|

Qualified plug placing |

≥99.8% |

|

Qualified cap screwing |

≥99.8% |

|

Compressed air required |

15m³/h 0.6-0.8MPa |

|

Total power |

6KW 380V(220V) 50HZ |

|

Net weight |

4800KG |

|

Overall dimension(L*W*H) |

9500*2150*2000(Exclude LAF) |

Mature Leading Edge Technology

u Advanced PLC control system, I/O online monitoring, full line is automatically running.

u Superelevation design of conveyor beyond machine table, make the laminar flow won't retum back on head of bottle mouth. All parts profile design on machine table is easily cleaned, no hygienic dead comers. Each working station are fully covered under laminar flow unit, full compliance with GMP requirements.

u Automatic unscrambling unit is streamline designed, both round bottle and flat bottles is suitable to be oriented in this unscrambler without human interference.

u Aseptic purified air washing bottle, plug and cap, the ion air eliminate the static electricity which attached on the bottle, plug, and cap.Linear bottle indexing device, one way blowing air into bottle inner, the other way suck and exhaust the waste air, ensure the bottle, plug, cap cleanliness without any pollution to working environment.

u Advanced ceramic piston pump dispensing mechanism, easy and reliable disassembling, cleaning, disinfection and sterilization;Pump isdriven by servo system, filling volume is easily set and changed in HMI;Precision bottle indexing device, neck clamping device, ensure filling nozzle right inserting into bottle mouth without any bottle falling dowm and other abnormal condition happens.

u Advanced plug vacuum pick and place unit, monobloc design with outer cap pick and placing unit, rotary planet driving system make machine running stably; Capping unit adopt magnetic adjustable torque clutch, suitable to different kinds of cap.

u Main driving parts of machine adopt low beat gear, rod and rock arm, ensure machine running stable and reliable. Very low noise occur.

u Key electrical elements, photo sensor, pneumatic components are famous name brand.

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

PXG/8 Spray Bottle Capping Machine

This series of machines is applied for screwing spray pump onto bottle mouth in industry of pharmaceutical and cosmetic field. As for the slim and long tube of the spray pump, this machine equip manipulate guider which can lead the long tube right into bottle mouth.

Learn MoreYG12/8 Series Rotary Liquid Filling and Capping Monobloc

This production line is mainly used in pharmaceutical, healthcare products such as oral liquid, syrup, liquor, healthcare product, tincture in different viscosity packing.

Learn MoreAVF Automatic sauce filling machine

AVF Automatic sauce filling machine is designed by referring to the same kind of foreign filling machines with extra functions increased The product is simple and convenient in operation, error correction, machine cleaning and maintenance. Widely used for filling various kinds of viscosity liquid products in the industries of, foodstuffs, pharmaceutics etc.

Learn More